Name: Lucy

Tel: +86-13312154946

E-mail: info@ystinjectors.com

Add: Jinyuan Building, 57 Hubin South Road, Xiamen, Fujian

Skype: yistong-cr@hotmail.com

whatsapp: 8613312154946

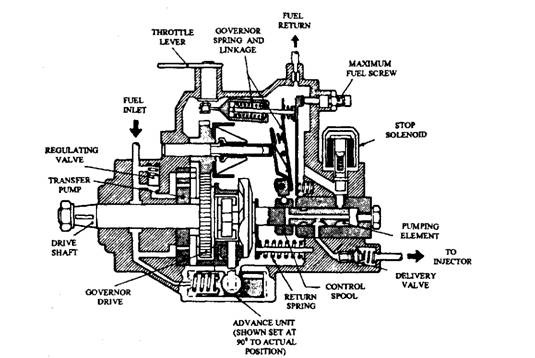

1. VE distribution pump timing adjustment when injection

First, align the VE pump timing gear with the timing mark, insert the VE pump into the inner tooth sleeve of the main shaft in accessory box, put on the VE pump fastening bolt, and gently rotate. Remove the inspection screw at the top of the VE pump plunger sleeve. Install the dial gauge probe to make it contact with the plunger. Then, turn the flywheel in the opposite direction to align the top dead center mark of the flywheel so that the first cylinder piston is at the advanced oil supply angle position before the top dead center. At this moment, it should be seen from the dial gauge that the plunger has just passed the plunger stroke of 1 mm from its bottom dead center. Otherwise, the VE pump body should be rotated to make it around the drive shaft, that mean, rotate the roller frame to an angle until The dial indicator shows that the plunger moves 1 mm. Finally tighten the VE pump.

2. Vehicle idle speed and maximum speed adjustment

The car's idle speed and maximum speed can be adjusted when the air filter is unobstructed, the coolant temperature is normal, and the transmission is in neutral.

When adjusting the idle speed, release the accelerator pedal, And check the joystick can touch the idle adjustment screw or not. Otherwise, adjust the throttle control mechanism to start the diesel engine. The idle speed should be 750r/min. If the speed does not match, adjust the idle adjustment screw, and adjust the throttle control mechanism after adjustment. When adjusting the maximum speed, press the accelerator pedal to the bottom. Also check the joystick can touch the high speed limit screw or not. Otherwise, adjust the stop screw under the accelerator pedal. Start the diesel engine and step on the accelerator pedal. The maximum speed should be 4650r/min. If the speed does not match, adjust the high speed limit screw. The adjustment should be made at idle speed, and then accelerate the inspection until it is suitable.

3. Inspection of VE pump parts

a. Plunger and spring Turn the plunger so that it does not get stuck at any position. It should be replaced if there is a stuck phenomenon. Pull out the oil control slip sleeve, pull out the plunger and then let go, the plunger should be able to sink from its own weight. For the plunger spring, the verticality can be checked with a steel ruler. The maximum error is 2mm. If it is too poor, it should be replaced.

b. Delivery valve and oil inlet solenoid valve Pull out the delivery valve, block the small hole of the valve seat with the thumb, and then put the oil discharge valve back to the valve seat. At this time, observe that the delivery valve should be able to sink freely; When blocking the small hole of the valve seat, press the delivery valve downward, and when it is suddenly released, the oil discharge valve should be able to rebound to the original position. If any of the above conditions are not met, replace the oil valve assembly.

The resistance of the oil inlet solenoid valve is 600 to 800 Ω. Listen to the operation to turn on and cut off the sound, and measure the resistance value. If it is not normal, replace the oil inlet solenoid valve.

c. Roller ring and Roller sets Mainly check the wear condition, measure its height, the deviation should be less than 0.02mm, if the tolerance is required to replace the whole set of components.

Common Rail Nozzles

Common Rail Nozzles